Engines for Africa Available Currently! Go To Our Relied On Vehicle Components Shop

The Pursuit for Ultimate Driving Power: Examining the Pinnacle of Engine Efficiency and Technological Breakthroughs in the Automotive Sector

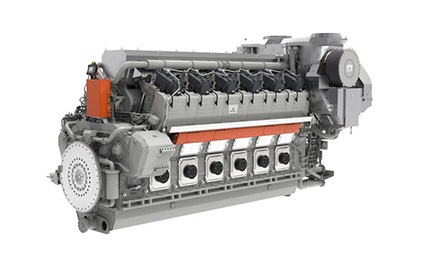

In the world of auto design, the pursuit of maximum driving power has been a relentless quest that has actually unravelled via the advancement of engine design and the combination of sophisticated technologies. From the precise workmanship of burning engines to the quick improvements in electrical propulsion systems, the automobile field stands at the cusp of a new age characterized by unmatched performance capabilities.

Advancement of Engine Layout

Additionally, the combination of turbocharging and supercharging technologies has reinvented engine style by increasing power without significantly boosting engine dimension. These forced induction systems compress the consumption air, enabling even more fuel to be ignited, consequently producing higher power outcome from a smaller engine. This improvement has actually been particularly critical in boosting the performance of smaller sized displacement engines while keeping fuel efficiency criteria.

Performance-Enhancing Fuel Technologies

The implementation of innovative fuel modern technologies has actually significantly added to boosting engine efficiency in contemporary vehicles. From typical gasoline and diesel to ingenious biofuels, artificial gas, and hydrogen, the vehicle sector is experiencing a change in fuel options. Biofuels, originated from renewable sources like algae, sugarcane, or corn, offer decreased exhausts and improved engine effectiveness. Synthetic fuels, produced with chemical processes, give high octane ratings, boosting power result. Hydrogen gas cells, although still in the early stages of adoption, reveal great pledge due to their zero-emission nature and capacity for high performance. Furthermore, gas ingredients and cleaning agents are being developed to clean engine components, optimize combustion, and minimize friction, thus boosting overall lorry efficiency. With recurring research study and development, the pursuit for the ultimate driving power proceeds, as designers aim to open the full potential of performance-enhancing gas technologies in the auto sector.

Improvements in Electric Propulsion

Substantial strides in electrical propulsion innovation have changed the automotive sector, leading the way for a new age of reliable and lasting transport. Electric lorries (EVs) are gaining appeal as a result of their ecological benefits and improvements in battery innovation, making it possible for longer driving varieties and much shorter charging times. Makers are spending greatly in r & d to enhance the performance of electric propulsion systems, concentrating on raising power output, improving energy efficiency, and reducing total weight.

One notable advancement in electric propulsion is the development of advanced electrical motors that supply greater torque and power thickness, leading to improved acceleration and general driving performance. Additionally, regenerative stopping systems have been improved to store and catch power during deceleration, more improving the performance of EVs.

Furthermore, the integration of smart innovations, such as expert system and predictive analytics, is enhancing the management of electrical propulsion systems, making certain optimal performance under different driving conditions. These innovations in electrical propulsion are reshaping the automotive landscape, driving the market towards a more sustainable and electrified future.

Effect of Computational Liquid Characteristics

With improvements in electric propulsion pushing the boundaries of vehicle innovation, the combination of Computational Fluid Dynamics is playing a pivotal duty in enhancing aerodynamic performance and boosting total performance in lorry design. Computational Liquid Characteristics (CFD) includes making use of computer simulations to evaluate the circulation of air around a vehicle, enabling designers to forecast exactly how design changes will impact aerodynamics without the need for expensive physical prototypes. By properly modeling air flow patterns, CFD enables the refinement of automobile forms to reduce drag, improve cooling, and improve stability.

One secret advantage of utilizing CFD in car style is the capacity to repeat rapidly, checking out many style variations to identify one of the most aerodynamically reliable remedies. This repetitive process causes lorries that are not just sleeker and a lot more visually appealing yet likewise extra fuel-efficient and eco pleasant. CFD makes it possible for engineers to enhance air movement around elements such as radiators, engine bays, and wheel wells, contributing to improved efficiency and general driving experience. To conclude, the assimilation of Computational Liquid Dynamics represents a significant action onward in the mission for ultimate driving power and efficiency in the automotive industry.

Future Patterns in Engine Technology

In the vibrant landscape of vehicle engineering, cutting-edge improvements are forming the future trajectory of engine advancement. The future of engine design is noted by a solid focus on effectiveness, efficiency, and sustainability. Suppliers are significantly focusing on developing engines that not just supply high power resource results yet additionally prioritize ecological duty by lowering exhausts and boosting gas effectiveness.

One noticeable additional reading pattern in engine development is the rise of electrification. Crossbreed and electrical powertrains are getting traction as feasible choices to traditional burning engines. These modern technologies provide the potential for substantial decreases in carbon discharges and enhanced energy effectiveness, straightening with global initiatives to fight climate change.

Additionally, advancements in materials scientific research and manufacturing methods are making it possible for the manufacturing of lighter and more long lasting engine parts. This shift towards lightweight materials such as carbon fiber and aluminum alloys contributes to improved performance and gas economy.

Verdict

Finally, the search of best driving power in the vehicle market remains to drive advancements in engine design, gas innovations, electric propulsion, and computational liquid characteristics. The development of these innovations is shaping the future of engine advancement, leading the way for much more reliable and effective cars (engines for africa). As the market remains to press the borders of what is possible, we can anticipate to see also a lot more cutting-edge growths in the pursuit for peak performance

One of the crucial landmarks in engine layout evolution is the change from traditional carbureted engines to modern-day fuel-injected systems. By specifically metering the gas delivery to each cyndrical tube, fuel-injected engines enhance combustion, resulting in better performance and minimized environmental effect.

Additionally, the combination of turbocharging and turbo charging innovations has changed engine design by their explanation enhancing power without considerably enhancing engine dimension (engines for africa).The execution of advanced fuel modern technologies has significantly added to boosting engine efficiency in modern-day cars. Additionally, fuel ingredients and cleaning agents are being developed to tidy engine elements, enhance combustion, and lower rubbing, thereby boosting general vehicle efficiency